This department is designed with Laboratories which have well maintained equipments.

Mechanical Engineering Laboratories

Applied Mechanics Lab

- Lab Incharge: Vallabh S. Prabhu Gaunker

Lecturer in Mechanical Engineering.

Goverment Polytechnic Curchorem

- Lab Objectives: –

-

- To verify various laws and machine equations.

- To help the student to identify parts, learn facts, develop conceptual understanding, solve problem solving, relate theoretical knowledge with practical and develop skills (Measurement, Experiments & Practicing) while demonstrating.

3. Lab Equipment’s: –

-

- Parallelogram law, Lami’s Experiment set up.

- Polygon Law universal force table set up.

- Inclined plane set up.

- Simple Lifting Machines like: –

-

-

- Simple Wheel and Axle

- Differential Wheel and Axle

- Single purchase Crab winch

- Double Purchase crab winch

- Screw Jack

- Jib cranes

- Fly wheel

- Worm and worm wheel set up

- Beam Experiment set up

-

4. Skill developed: –

-

- It will help the students to develop conceptual understanding and relate it with practicals.

- It will help students to verify laws in mechanics.

- Student will learn measurements, calculations and concluding the results of experiments.

- It will develop skills like communication, Team work, problem solving, and analytical & graphical skills.

Fluid Machinery Lab

- Lab In charge: Vallabh S. Prabhu Gaunker

Lecturer in Mechanical Engineering.

Government Polytechnic Curchorem

- Lab Objectives: –

-

- To deliver and provide knowledge to apply concepts in fluid machinery.

- Students will get acquainted with various hydraulic systems.

- Apply laws and theorems on fluid statics and fluid dynamics.

- Student will learn measurements, calculations and concluding the results of experiments.

- It will develop skills like communication, Team work, problem solving, and analytical & graphical skills.

- Lab Equipments:-

-

- Bernoulli’s Experiment test rig

- Orifice Experiment test rig

- Losses in pipe fitting apparatus

- Pitot tube test rig

- Venturi meter and orifice meter test rig

- Pelton wheel turbine test rig

- Centrifugal pump

- Notch experiment test rig

- Models of pump impellors and turbines vanes.

- Skill developed by the students.

-

- Conceptual understanding and feeling of handling the experiment.

- Skill like measurement, calculations, problems solving, physically conducting experiments, and controlling parameters.

- Team work, Leadership and communication.

Engineering Metrology & Quality Control Laboratory

Lab incharge: Shri Paresh P. Panshikar, Lecturer in Mechanical Engineering

The M&QC laboratory which is one of the important laboratories in the Mechanical Engineering. Keeping in view the demand the section has a vision to enrich the knowledge of students and update the latest technology in M&QC. The section has a team of qualified & experienced faculty and staff members.

The section has well equipped laboratory includes components such as VC, SG, Sine bar, Plugs, Profile projector, Roughness tester, Parkinson gear tester etc.

As a demand of an industry the students are exposed to new technology. They are encouraged to improve technical skills to gain employment in the areas such as measurements, Quality control, repair & maintenance.

We have a workshop which is fully equipped with newer tools where our students encouraged handling almost all available tools.

Lab objective:  To make student:

- To apply metrology in industry with ethical responsibility.

- Study and selection of proper measurement systems

- Study the measuring instruments and to develop an ability to engage in lifelong learning.

- Use Quality control in an industry as well as in a global and societal context.

Lab equipments:

- Universal bevel protector- Optical type

- Combination square set

- Vernier calliper :

- Mechanical VC with fine adjustment

- Digital VC

- Screw gauge digital

- Gear tooth vernier calliper

- Toolmakers microscope

- Depth gauge

- Dial indicator

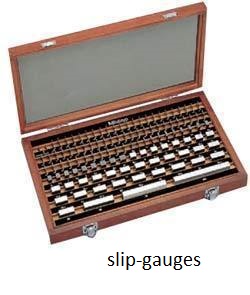

- Slip gauges

- Surface roughness tester

- Optical Profile projector

- Optical flats

- Parkinson gear tester

- Clinometer

- Sine bar

- Thickness gauge

- Angle gauges

- Steel “V†block

- Magnetic stand with holding arm of dial gauge

- Plug gauges

- Filler gauges set

- Granite surface plate

- Adjustable snap gauge

- Angle plate

- Length bar

- Spirit level

- Radius gauge:

- Concave circular profiles

- Convex circular profiles

List of experiments/skill developed:

- Use of basic measuring instruments.

- Use of Dial indicator.

- Use of Sine-Bars to measure angle.

- Study on Calibration of Vernier caliper

- Measurement of different Parameters of Gear.

- Measurement of different Parameters of screw thread

- Demonstration of optical flats using monochromatic light source.

- Demonstration of Tool Maker’s microscope/Profile projector.

- To draw and interpret the control limit for variable measurement (X, R and P Chart).

Automobile Engineering Lab

Lab incharge: Shri Paresh P. Panshikar, Lecturer in Mechanical Engineering

The Automotive Components laboratory which is one of the important laboratories in the Mechanical Engineering was established in the academic year 1998-99. Keeping in view the demand for automobile engineers the section has a vision to enrich the knowledge of students and update the latest technology of automobile engineering. The section has a team of highly-qualified and well-experienced faculty and staff members.

The section has well equipped laboratory includes components such as Chassis, clutches, gear boxes, steering gears & mechanisms, differential, suspension systems, electrical systems etc.

As a demand of an industry the students of automobile engineering are exposed to latest technology. They are encouraged to improve technical skills to gain employment in the areas such as automotive design, repair & maintenance.

We have a workshop which is fully equipped with latest machines where our students used to fabricate their vehicles as a part of project work.

Lab objective:  To make student:

- Understand the basic principles in the areas of automobile engineering.

- Aware about the components, assembly, relative movements among different parts, handling different material components.

- Develop initiating & leadership quality

Lab equipments:

- Working model of a Jeep chassie.

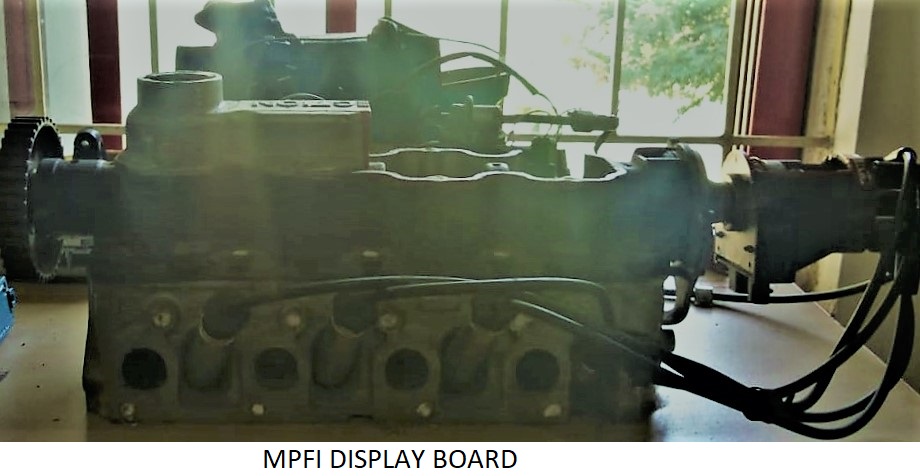

- Demonstration board of MPFI system

- Demonstration board of Ignition system

- C/s model of Starter motor

- Front steering linkage system

- Working models of a steering mechanism:

- Ackerman type

- Davis type

- Working model of power steering mechanism

- C/s models of steering gear mechanisms:

- Rack-N-Pinion,

- Recirculating ball,

- Worm-N-Worm,

- Worm-N-Sector,

- Worm-N-Nut,

- Worm-N-Peg.

- C/s model of single reduction industrial gear box

- C/s model of single plate coil spring type clutch system

- C/s model of Centrifugal clutch

- C/s model of Multi-plate clutch

- C/s model of Torque convertor

- C/s model of Sliding mesh type Gear box

- C/s models of Synchromesh gear boxes of:

- Car

- Sedan

- HTV

- C/s model of Epicyclical gear box

- C/s model of Transfer case

- C/s model of Shock absorber

- C/s model of Complete McPherson strut with drive shaft & Disk

- Double wishbone type front independent suspension system

- C/s model of Propeller shaft

- Mock wire model of a Car

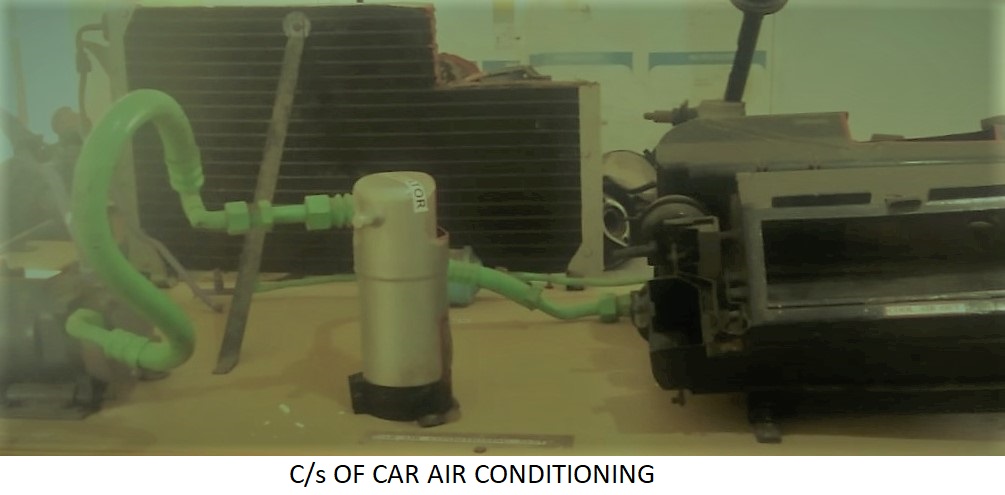

- C/s model of Air-conditioning system

- C/s model of Catalytic convertor with Outlet manifold

- Display charts of:

- Pressure Lubrication system

- Clutch mechanism

- Exploded view of Starter motor

- Working model of Dual circuit braking system

- Starter motor

List of experiments/skill developed:

- Dismantling and assembly of petrol engine.

- Dismantling and assembly of diesel engine.

- Replacement of friction plate in single plate dry clutch.

- Dismantling and assembly of synchromesh gear box.

- Removal of final drive and differential assembly , checking and adjustment for proper tooth contact and backlash between the pinion and crown wheel.

- Tracing of the air conditioning circuits of an automobile and identifying the different components and learning the charging procedure.

- Replacement of brake shoes/ linings and friction pads (disc brakes), replacement of master cylinder and wheel cylinder kits.

- Replacement of tie rods or tie rod end of steering linkage.

- Replacement of bushes in leaf spring suspension system.

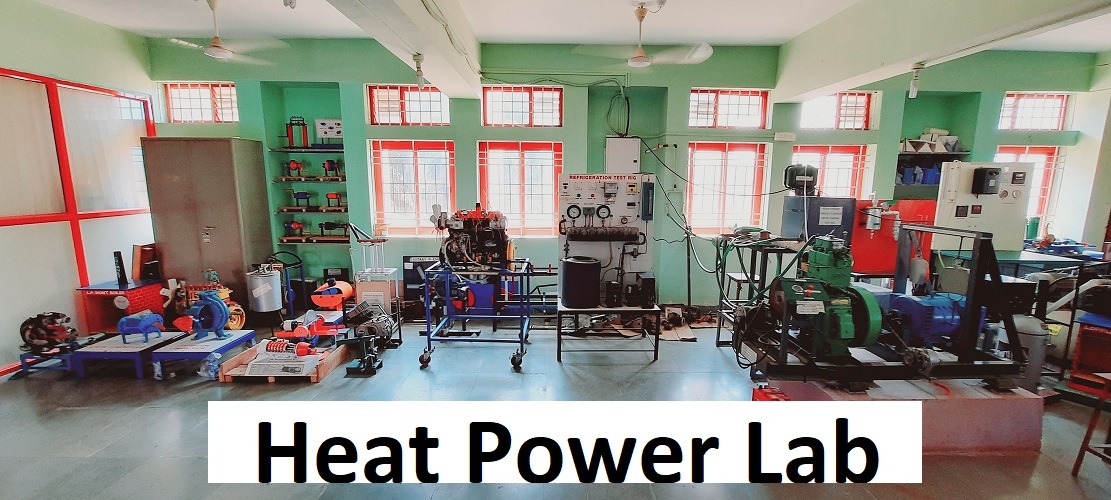

Heat Power Lab

Lab I/c : Shri Devanand Desai ( Lecturer in Mechanical Engineering)

Lab Objective:  1. To be acquainted with construction and working of various heat transfer equipments and machineries.

2.To determine working parameters and efficiency of heat transfer equipment’s by conducting related experiments.

Details of Lab Equipment

| Sr No | Equipment | Qty |

| 1 | Four Stroke Single cylinder petrol engine test rig w/electric loading | 1 |

| 2 | Two Stage Air Compressor Test Rig | 1 |

| 3 | Separating Steam Calorimeter | 1 |

| 4 | Cut section of Model of 4 stroke Petrol engine | 1 |

| 5 | Cut section of Model of 4 stroke Diesel Engine | 1 |

| 6 | Cut section of Model of 2 stroke Petrol engine | 1 |

| 7 | Cut Section model of Turbocharger | 1 |

| 8 | Cut Section model of Carburettor | 1 |

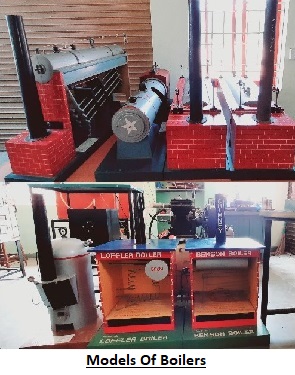

| 9 | Model of La Mont Boiler | 1 |

| 10 | Model of Benson Boiler | 1 |

| 11 | Model of Loffler Boiler | 1 |

| 12 | Model of Babcock & Wilcox Boiler | 1 |

| 13 | Model of Lancashire Boiler | 1 |

| 14 | Model of Locomotive Boiler | 1 |

| 15 | Model of Cornish Boiler | 1 |

| 16 | Model of Cochran Boiler | 1 |

| 17 | Model of Axial Flow Compressor | 1 |

| 18 | Model of Centrifugal Compressor | 1 |

| 19 | Model of Screw Compressor | 1 |

LIST of EXPERIMENTS

- To Identify the various parts of IC Engine

- To conduct a test on diesel engine and determine its brake power, brake thermal efficiency and brae specific fuel consumption and prepare a Heat Balance Sheet for any Load

- To study Different Boilers, their mounting and accessories

- To find the dryness fraction of steam using Separating Steam Calorimeter

- To demonstrate the working of Multistage Air compressor with intercooler